We offer custom services to meet a variety of industry needs, including custom fiberglass solutions for electronics, wind turbines, automotive, shipbuilding and military applications. Our expertise in product customization ensures we provide an effective solution for any application.

Fiberglass R & D Service

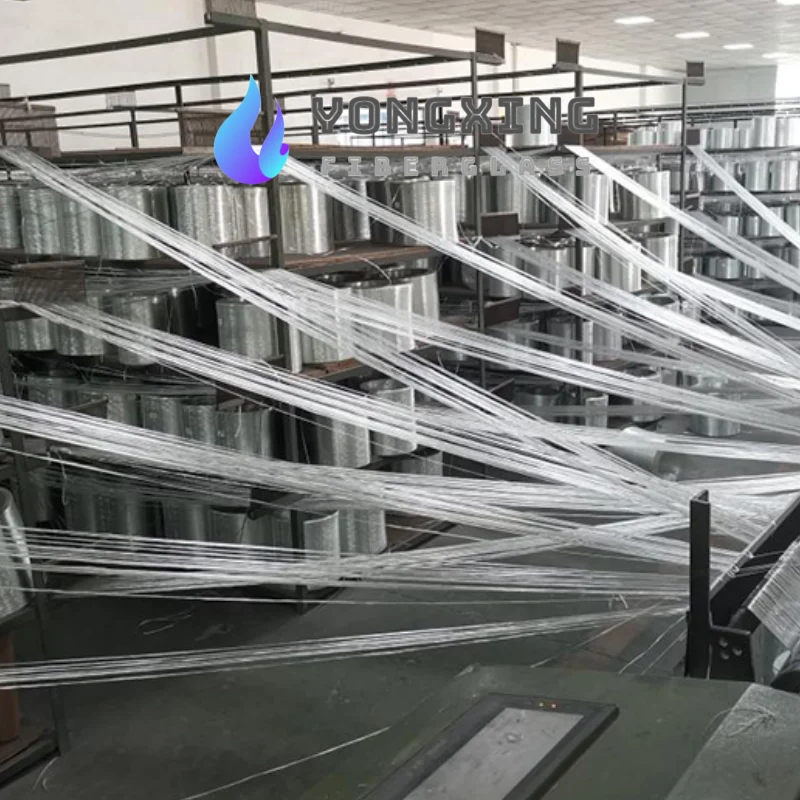

YONGXING Fiberglass stands as a leader in the fiberglass manufacturing industry, with over thirty years of excellence and innovation. Committed to superior quality and cutting-edge technology, we excel in the research and development of advanced fiberglass products. Our expertise spans the entire process of design, development, and production, ensuring that each product meets and exceeds industry standards.

At YONGXING Fiberglass, we are dedicated to advancing technology and pushing the limits of fiberglass applications. Our extensive product line includes Fiberglass Chopped Strand, Fiberglass Roving, Chopped Fiberglass, Fiberglass Mat, Fiberglass Fabric, Fiberglass Sheet, Fiberglass Grating, and other specialized products. Our ability to innovate and customize solutions allows us to meet the diverse needs of our clients, providing reliable and efficient fiberglass solutions for various applications.

Contact usOur R & D Capabilities

At Yongxing Fiberglass, excellence in research and development is the cornerstone of our success and innovation in the fiberglass industry. For more than three decades, we have been at the forefront of the development of fiberglass technology through continuous research and development efforts. Our talented team of engineers, researchers and technicians embody our commitment to innovation, driving us to explore new areas of fiberglass application. From electronics and wind turbines to automotive, shipbuilding and military fields, we continue to push boundaries and provide cutting edge solutions to ensure Yongxing Fiberglass maintains a leading position in diverse and demanding industries.

Material Research and Innovation

Our ongoing research focuses on enhancing fiberglass materials and manufacturing technologies. By exploring new insulation, reinforcement, and composite materials, we continuously improve the performance, efficiency, and sustainability of our fiberglass solutions.

Prototyping, Testing, and Compliance

With prototyping and testing facilities, designs are rigorously validated to meet stringent quality standards. Our commitment to regulatory compliance ensures our fiberglass products meet safety, performance and environmental regulations.

Customization and Applications

Fiberglass Design Styles and Cases

As a leading fiberglass manufacturer, YONGXING specializes in producing a diverse range of fiberglass products, including Fiberglass Chopped Strand, Fiberglass Roving, Chopped Fiberglass, Fiberglass Mat, Fiberglass Fabric, Fiberglass Sheet, and Fiberglass Grating. Our expertise extends to custom solutions, ensuring that each product is tailored to meet your specific requirements. Whether you need standard fiberglass materials or bespoke solutions, our custom services are ready to cater to your needs.

Fiberglass Direct Roving

Glass fiber is primarily used in the wind energy sector for manufacturing wind turbine blades and hub covers. Known for its excellent weaving performance, wear resistance, and minimal fuzz, it is well-compatible with epoxy and vinyl resins. Its lightweight, high strength, and strong load-bearing capacity make it crucial for enhancing the overall performance and durability of wind turbines, ensuring their reliable operation in harsh environments. YONGXING collaborates with several Chinese wind power manufacturing companies to provide best ECR glass fiber direct roving for wind energy applications.

Professional Product Services

Support throughout the entire life cycle of your product.

YONGXING is a leading fiberglass manufacturing company, and we are committed to providing comprehensive services throughout the lifecycle of your fiberglass products. Our support includes expert guidance and technical assistance to ensure that your fiberglass solutions, such as fiberglass sheets, fiberglass rovings, fiberglass fabrics, and fiberglass mats, maintain their superior strength, lightweight properties, and heat and corrosion resistance. We regularly provide updates and enhancements to keep your products up to date with the latest technological advances, ensuring optimal performance and longevity. In addition, our dedicated team provides detailed product education and training to help you get the most out of your fiberglass solutions. With Yongxing, you can be confident that your fiberglass products will receive the highest level of care and attention, ensuring they continue to be reliable and efficient throughout their service life.

Contact us