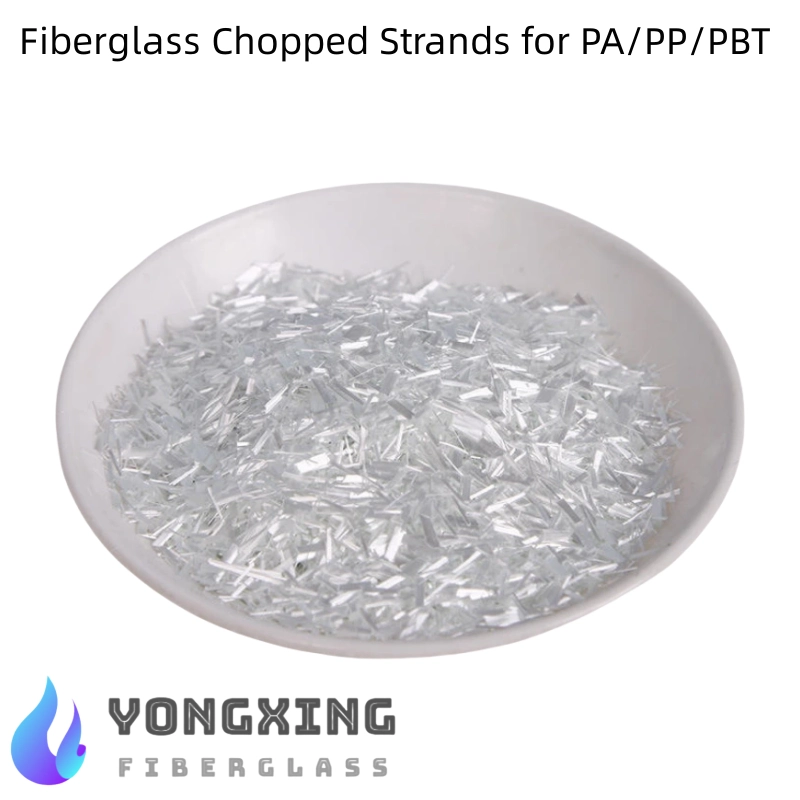

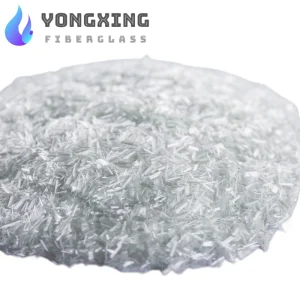

PA/PP/PBT Fiberglass Chopped Strand Raw Materials

YONGXING Fiberglass Chopped Strand are crafted from high-quality E-glass, renowned for its excellent mechanical properties and durability. E-glass is selected for its superior strength, flexibility, and resistance to high temperatures and chemical exposure. The raw materials are sourced from top-grade silica sand, ensuring purity and optimal performance in various composite applications.

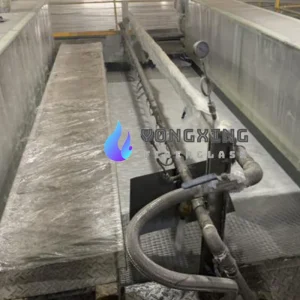

PA/PP/PBT Fiberglass Chopped Strand Manufacturing Process

The production of our Fiberglass Chopped Strand involves several advanced steps:

- Fiber Production: Continuous glass fibers are produced by melting silica sand and other raw materials in a high-temperature furnace. The fibers are then drawn through fine nozzles to achieve the desired diameter.

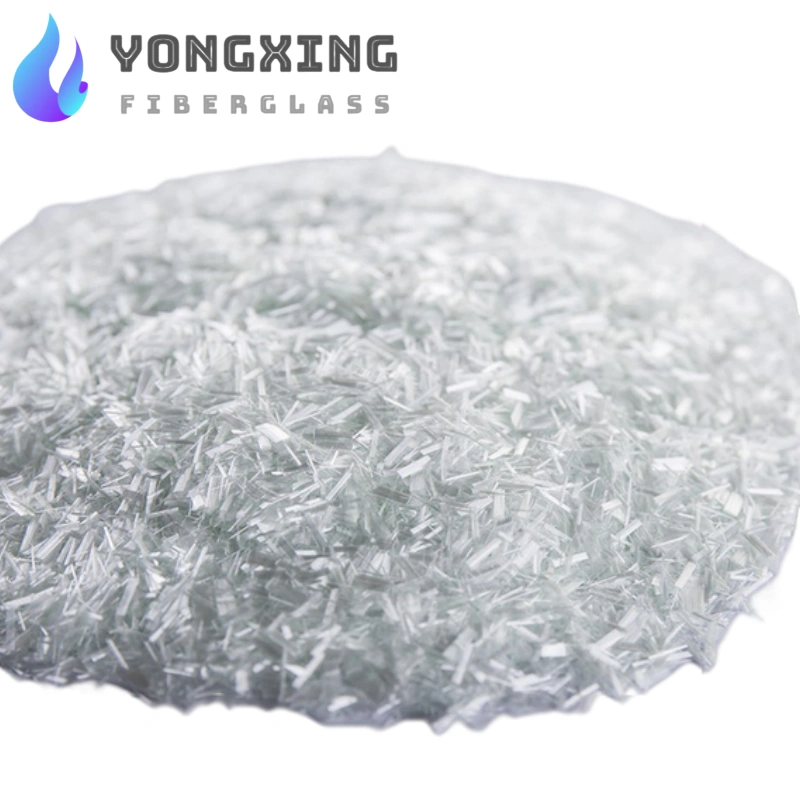

- Chopping: These continuous fibers are cut into short, uniform strands. Our process allows for precise control over strand lengths, typically available in 6mm, 9mm, and 12mm, ensuring consistency and suitability for different applications.

- Sizing Application: A specialized sizing agent is applied to the chopped strand. This treatment enhances the adhesion between the fiberglass and various polymer matrices, including PA, PP, and PBT, improving overall composite strength and performance.

- Blending and Packaging: The treated chopped strands are blended and packed in standard international export packaging to maintain product integrity and facilitate efficient handling.

Read More:Fiberglass Woven Roving

PA/PP/PBT Fiberglass Chopped Strand Product Features

- Enhanced Strength: The chopped strand significantly improve the mechanical strength and impact resistance of PA, PP, and PBT composites.

- Uniform Distribution: Consistent strand length and distribution ensure uniform reinforcement and reliable performance.

- Superior Adhesion: Specialized sizing enhances bonding with resin matrices, resulting in stronger and more cohesive composites.

- Durability: Offers excellent resistance to environmental and chemical factors, ensuring long-lasting performance in diverse applications.

- Versatility: Suitable for a wide range of applications, including automotive parts, industrial components, and consumer goods.

PA/PP/PBT Fiberglass Chopped Strand Applications

YONGXING Fiberglass Chopped Strands are ideal for use in:

- Automotive Industry: Enhancing the durability and strength of automotive components such as bumpers, dashboards, and structural elements.

- Industrial Components: Reinforcing parts in machinery, equipment, and structural components to withstand high stress and environmental conditions.

- Consumer Goods: Improving the performance and longevity of various consumer products made from PA, PP, and PBT.

- Electronics: Providing strength and durability in electronic housings and components.

Read More:A Comprehensive Overview of Glass Fiber Classifications

PA/PP/PBT Fiberglass Chopped Strand Typical Product Parameters

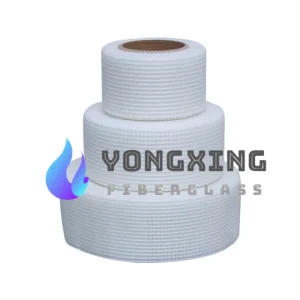

- Strand Length: Available in 6mm, 9mm, and 12mm, with customization options based on specific needs.

- Density: Designed for optimal reinforcement and mat formation.

- Sizing Type: Customized to enhance compatibility with PA, PP, and PBT resins.

- Packaging: Standard international export packaging to ensure product quality during transit.

Brand and Supply

YONGXING Fiberglass is a leading fiberglass manufacturer in China, recognized for our comprehensive expertise and advanced production capabilities. We offer factory-direct wholesale pricing on our best Fiberglass Chopped Strand for PA, PP, and PBT. For more details or to place an order, please contact us directly. Our team is dedicated to providing tailored solutions and ensuring the best value for your composite needs.

Contact YONGXING Fiberglass today for superior products and exceptional service!

Reviews

There are no reviews yet.